Article : La Nouvelle République, 21 May 1999

![]() Download the original article in french

Download the original article in french

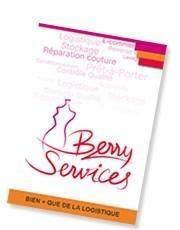

Berry Services, of Neuvy-Saint-Sépulchre, prefers a skilled workforce to diplomas.

Unlike his fellow entrepreneurs, Jean-Claude Benéteau does not look for qualified staff with piles of diplomas. What his company, which specialises in precision assembly, mechanic assembly, and packaging in all its forms, essentially needs is a skilled and motivated workforce. Having set up his company in Neuvy-Saint-Sépulchre a few months ago, he has found the secret ingredient required for the site’s development—women from the decimated clothing industry. These little hands hold the key to a project that came to fruition last year. Jean-Claude Benéteau was at a crossroad at the time. Originally from the La Vendée département, he had arrived in the Indre département in 1989 after graduating from a mechanical engineering degree. Having worked for seven years at Mead Europe, as production manager, he joined the company Simade de Montierchaume, but his desire to set up his own business drove him to go further. He says: “I was beginning to know the packaging sector very well and I felt that we could do something here. So, I did an internship at the Chamber of Trades before creating my own company.”

A favourable context

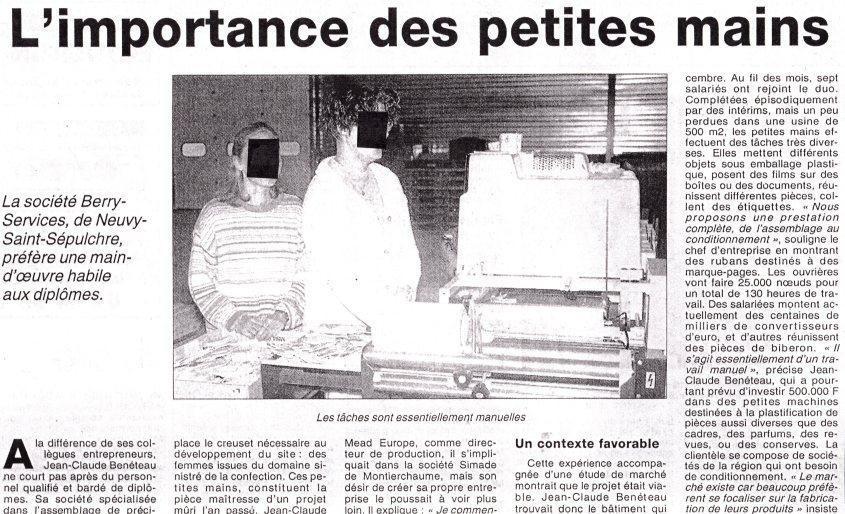

This experience, along with a market study, suggested that the project was viable. Jean-Claude Benéteau then found the building that suited him in the Le Fay small business area, in Neuvy-Saint-Sépulchre, and launched the LLC Berry Services. He started prospecting alone in October 1998, then took on a sales representative in December. Over the months, seven employees have joined the duo. Occasionally supplemented by temporary workers, but a little lost in a 500 m² factory, these little hands perform a wide variety of different tasks. They put different objects in plastic packaging, film wrap boxes and documents, assemble various parts, and stick on tags. “We offer a comprehensive service, from assembly to packaging,” says the company director, holding up ribbons to be made into bookmarks. The workers are going to make 25,000 bows, for a total of 130 hours of work. Some employees are currently assembling hundreds of thousands of euro converters, and others are putting together baby bottle parts. “It is essentially manual work,” says Jean-Claude Benéteau, who nonetheless plans to invest 500,000 francs in small machines for laminating items ranging from frames, perfumes, magazines and preserves. The customer base comprises companies from the region with packaging needs. “The market exists because many prefer to focus on making their products,” says the young industrialist who used nine hundred hours of temporary work in March/April. He hopes to employ twenty-five people in the next three years. Without going hunting for diplomas, however.

Jean-Michel Bonnin